Meringues (fr. meringue) are light and delicate confectionery made from whipped egg whites and sugar or syrup. As a rule, meringues are called products without heat treatment, but they can also be dried in the oven to a crisp state. There are many recipes for making meringues, the most famous among them are French, Swiss and Italian meringues.

Technical data of the set

| Productivity, kg / h | 40-50 |

| Installed power, kW (for an electric furnace) | 60 |

| Production area, square meters | 60-100 |

| Service personnel, person | 3-5 |

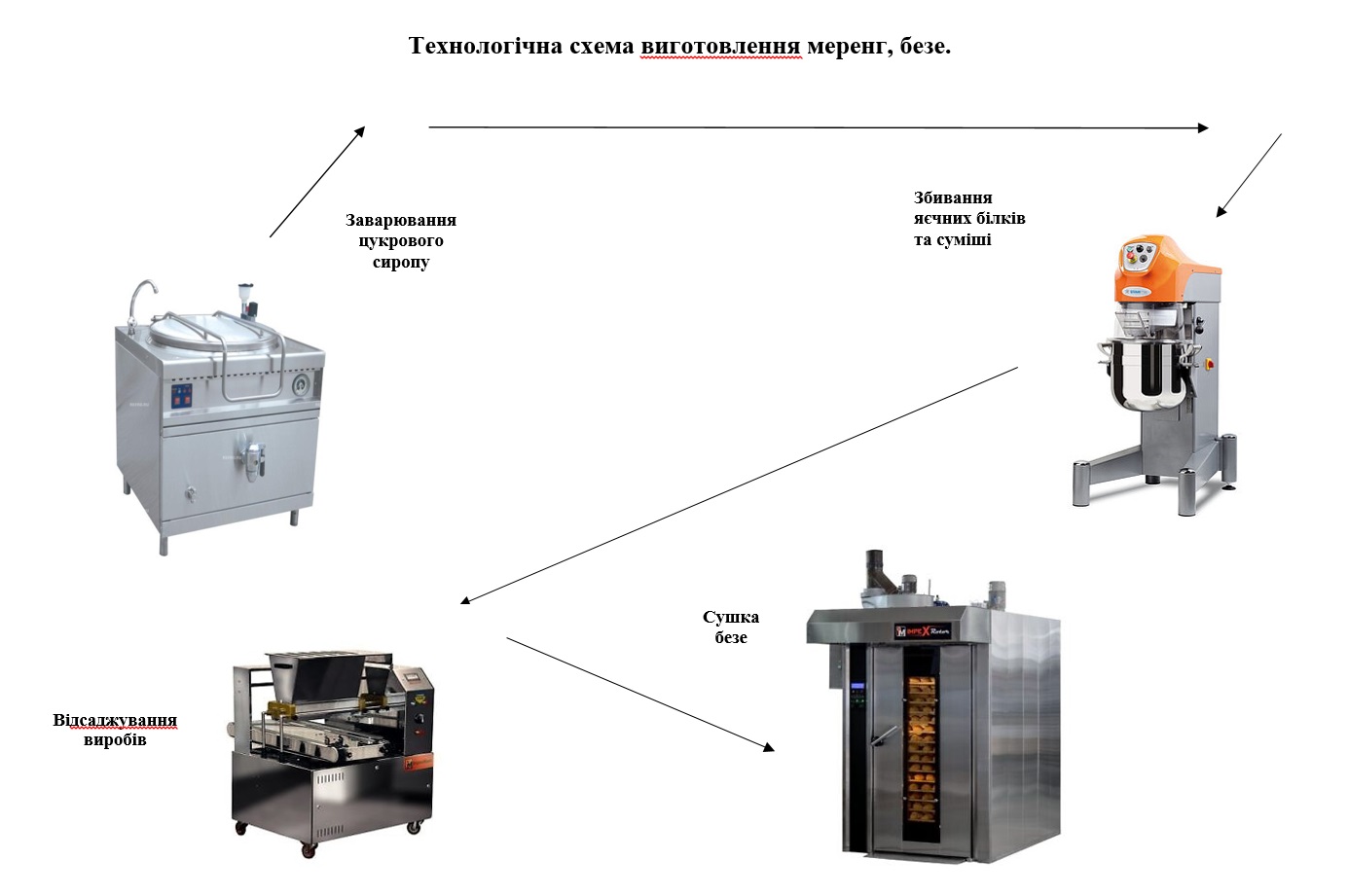

The technological process of meringue production consists of the main stages:

1. brewing sugar syrup;

2. preparation of the mixture (beating proteins, mixing with sugar or syrup);

3. product formation;

4. drying in the oven (for meringue);

5. cooling;

6. packaging

Functional composition

| Equipment | Number |

| Cooking boiler | 1 |

| Mixer Starmix PL60/PL80 | 1 |

| Dropping machine ImpexDrop-600 | 1 |

| Rotary oven Impex Rotor (pellet, gas, electric, diesel) | 1 |

| Shelving cart IR/22 | 4 |

| Floor sheet 600*400 (mm) | 176 |

To prepare meringue, egg whites are whipped in a Starmix mixer until thick foam. The volume should increase approximately 8 times. Then, depending on the recipe, sugar or hot sugar syrup is gradually added. For this purpose, the syrup is heated in a boiler. The finished mixture is fed to the ImpexDrop-600 Planting Machine for forming. The dough is loaded into the hopper, passes through the pumping shafts, then through the nozzles it is pressed onto metal sheets covered with parchment or silicone mats. The shape depends on the tips on the nozzles, as well as on the available functions and settings of the depositing machine. The ImpexDrop-600 dropper features sheet pulling, nozzle rotation, and table raising and lowering functions, enabling the production of a significant number of product shapes with a relatively small range of nozzles.

Next, the products are dried for 1-1.5 hours in a heated Impex Rotor rotary oven.