It is intended to impart a cylindrical shape to the pre-rounded dough pieces and is used for the production of a wide range of bakery products as part of lines with a capacity of up to 3000 pieces per hour. Thanks to reliable design, the presence of adjustments that ensure accurate operational tuning and advanced technological capabilities, the Impex Roll-500 dough moulding machine allows you to obtain attractive appearance products with a good crumb. For the production of high-quality products, it is advisable, after rounding, to apply preliminary proofing of the dough pieces using a preliminary proofing cabinet.

| Specifications: | |

| Capacity, pcs./h, (pcs./min) no more Weight of dough pieces, kg Moisture of dough pieces, % Length of dough pieces, mm, no more Diameter of dough pieces, mm, no more Width of conveyor belt, mm Width and Lenght of plate, mm Nominal power consumption, kW Nominal voltage, V Overall dimensions, mm: – Length (Length with tray), mm – Width, mm – Height, mm The height of the workpiece exit (the surface of the tape) Weight, Kg |

3000 (50) 0,09-1,1 39-44 500 120 550 550×1200 1,9 3NPE~3802510 (2980) 879 1370760…810 380 |

- the ability to work with a wide range of dough pieces can be molded as pieces for bakery products, and pieces for molded and toaster breads

- The hopper is equipped with an adjustable centering device for dough pieces

- It is possible to quickly and easily adjust:

- gaps of the upper and lower pairs of rolling rolls with the help of steering wheels with noniuses

- the distance between the molders of the ends of the dough pieces, which can be determined from the ruler

- height of the clamping plate at the input and output of the workpiece

- rolling rolls are made of anti-adhesive polymer with increased wear resistance

- rolls of the upper pair have reefs that improve the grip of workpieces

- The width of the opening of the rolls is 140mm. allows you to handle large pieces

- the lower pair is equipped with scrapers that prevent the dough from sticking to the rolls

- the working surfaces of the grinding plate and guiding elements (the molders of the ends of the dough pieces) are made of anti-adhesion food plastic.

- All materials in contact with the dough are approved for use in the food industry

- Four rotary roller bearings, two of which are fitted with latches, allow you to move the machine through the production room and fix it in the working position

- The safety of personnel during operation and maintenance is provided by the presence of safety devices and a locking system: two emergency stop buttons located in the personnel work area, the protective enclosure of the loading hopper, the interlock switches installed on the transparent hinged covers of the rolling roll unit

- the tempering plate can be folded back and fixed in the folded state for easy cleaning and maintenance, transparent hinged lids facilitate access to the rolling roll unit and allow visual control of the work

- multilayer seamless conveyor belt from the best European manufacturers has high operational properties, wear resistance, and the conveyor design eliminates the slipping of the conveyor belt during operation

- the possibility of changing the height of the conveyor for agreement with subsequent equipment by means of adjustable supports.

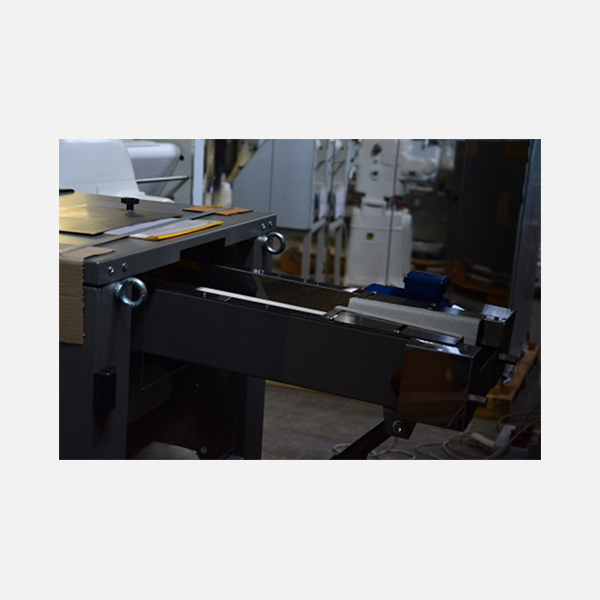

- The machine can be equipped with an integrated feed conveyor, which allows you to receive the workpieces directly from the cone round.

Reviews

There are no reviews yet.